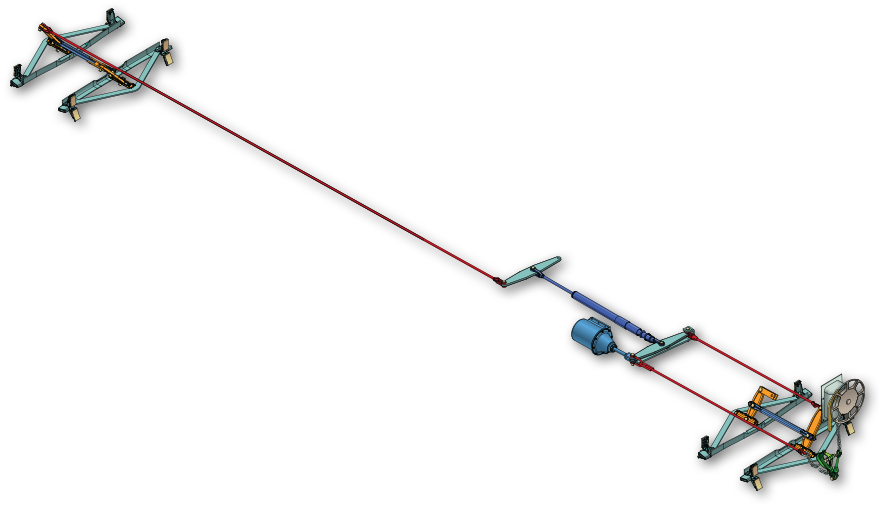

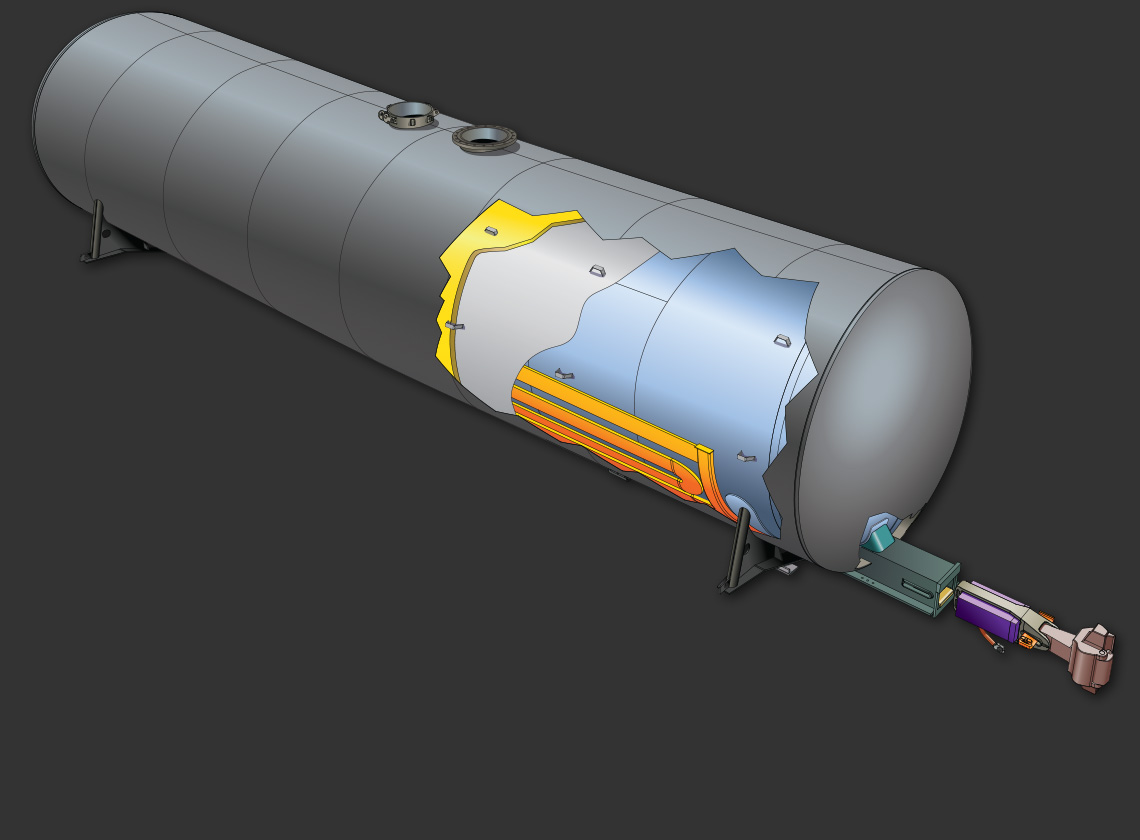

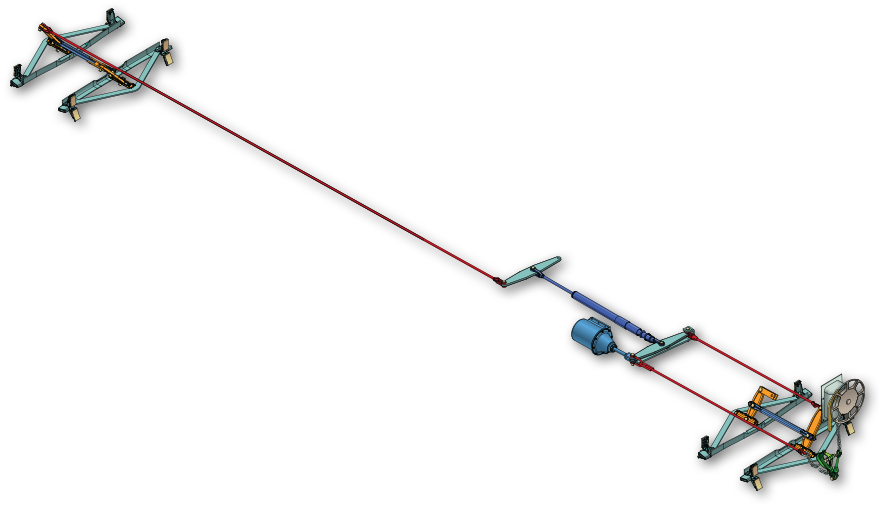

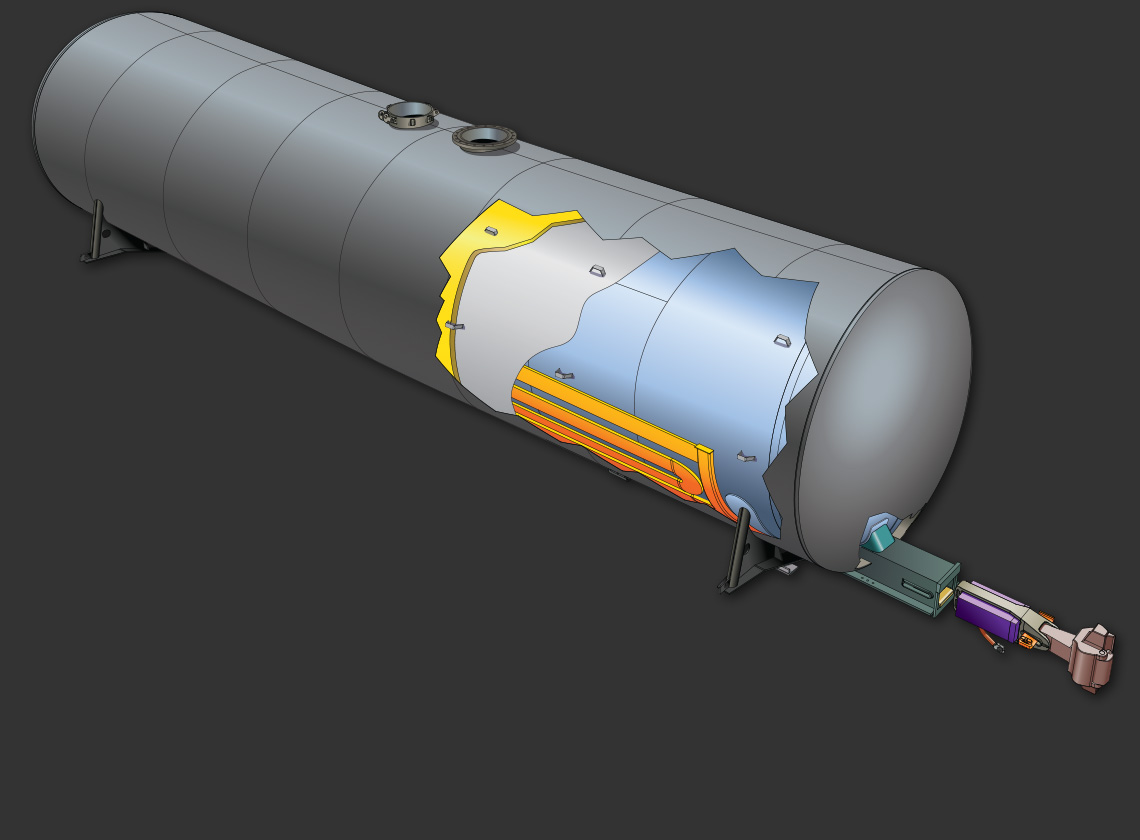

With the jacket applied and fully welded, the remaining brake rigging supports are welded in place to accommodate the rods, levers, piping, and devices that brake the car. Most UTLX tank cars are equipped with body-mounted brake assemblies, as shown in the DOT-117J100W car in the drawing. The brake cylinder and control valve are mounted on the "B-End" or hand-brake end of the car. Some UTLX tank cars are equipped with truck-mounted brakes, which have the brake cylinder mounted directly to the truck assembly.

Once all the braking hardware has been applied and adjusted, the pneumatic portion of the system is evaluated with an Automated Single Car Air Brake Test. This test ensures there are no restrictions or leaks in the air piping and verifies the control valve, auxiliary, and emergency air system functions as required. After passing the Automated Single Car Air Brake Test, the system is subjected to a Brake Shoe Force Test as well as a Curve Test.

The Brake Shoe Force Test ensures the required range of braking force to each brake shoe is met and that the force at each shoe meets the car's braking force design per AAR requirements. The Curve Test ensures that there is no fouling contact between brake rigging and body or truck components that will hinder the application of the brakes. The Curve Test also tests the manual braking system by applying the hand brake. While UTLX ensures that your tank cars have stopping power, there is no stopping Union Tank Car Company from meeting all your tank car needs.